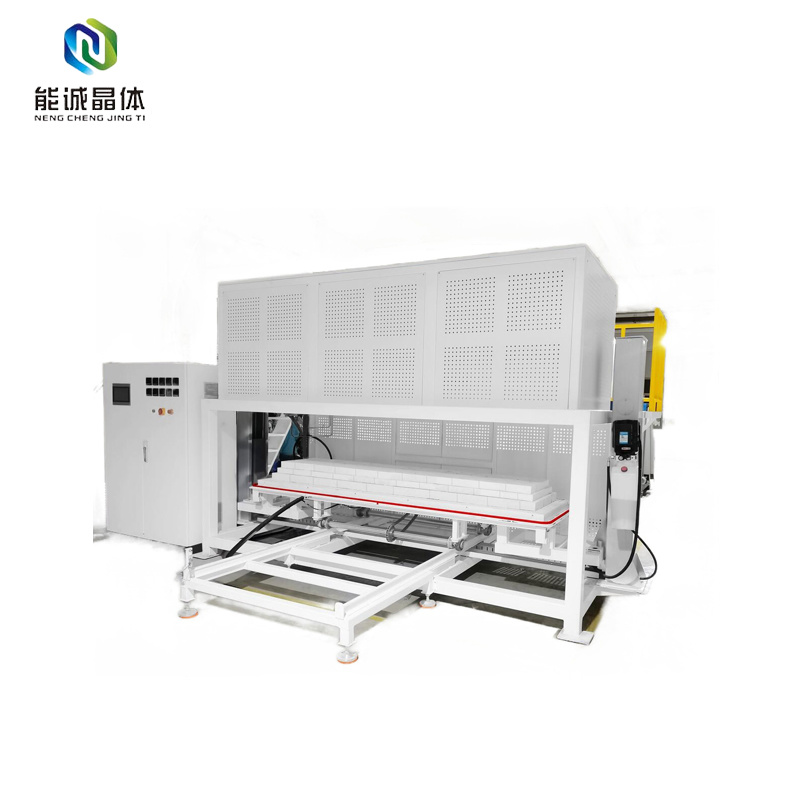

Industrial lifting furnace

Classification:

keyword:

Industrial lifting furnace

E-mail:ncjt@zjncjt.com

Product Details

This vertical vacuum carbon tube furnace uses graphite electrodes, which are connected to the graphite heating element through cylindrical contact. One end of each electrode is sealed and extends outside the furnace. It is an important component that allows current to pass through the heating element inside the furnace, with uniform heating and good pressure resistance. The heating element is surrounded by a multi-layer radiation screen insulation device. The inner layer of the furnace shell is made of stainless steel, and the outer layer is made of carbon steel. There is a water cooling system between the two layers for cooling. The temperature of the outer shell is ≤ 50 ℃, which can achieve high-temperature sintering in a completely oxygen free state. The furnace is made of ceramic alumina fiber, which has good insulation performance and high cleanliness. Widely applicable to the sintering preparation of inorganic materials (such as ceramic seals, silicon carbide, zirconia, zinc oxide, alumina, etc.) and metal materials (such as hard alloys) in vacuum or protective atmosphere, and can also be used for the purification treatment of rare earth elements and their oxides and the annealing treatment of sapphire.

| Furnace size (mm) | Maximum temperature (℃) | Heating element | Power (KW) | Voltage | heating rate |

|

φ1000*1000*1000 |

1200℃ | Resistance wire | 110 |

220/380V |

1-20℃/MIN |

|

φ1850*700*600 |

90 | ||||

|

φ1350*600*600 |

1400℃ | Silicon carbide | 75 | ||

|

φ2400*800*800 |

185 | ||||

| φ1000*1000*1000 | 120 | ||||

| φ1100*1000*1000 | 105 | ||||

| φ500*500*500 | 35 | ||||

| φ800*500*500 | 60 | ||||

| φ1350*500*500 | 1700℃ | Silicon molybdenum rod | 80 | ||

| φ2400*500*500 | 150 | ||||

| φ2400*700*700 | 220 |

Recommend products

Online consultation