What is aluminum silicate fiber board: the workplace can not know the efficient insulation material

Release time:

2022-05-10 10:24

Exploring the aluminum silicate fiber refractory board: an industrial protection weapon that professionals cannot know

In the fast-paced workplace environment, especially for professionals involved in high-temperature industries such as chemical industry, metallurgy, and building materials, equal emphasis on safety and efficiency is an eternal pursuit. Today, let us unveil a material that plays an important role in the field of industrial protection-aluminum silicate fiber refractory board, and discuss why it can become a trusted partner for many professionals.

1. first knowledge of aluminum silicate fiber refractory board: what is the soul of "refractory?

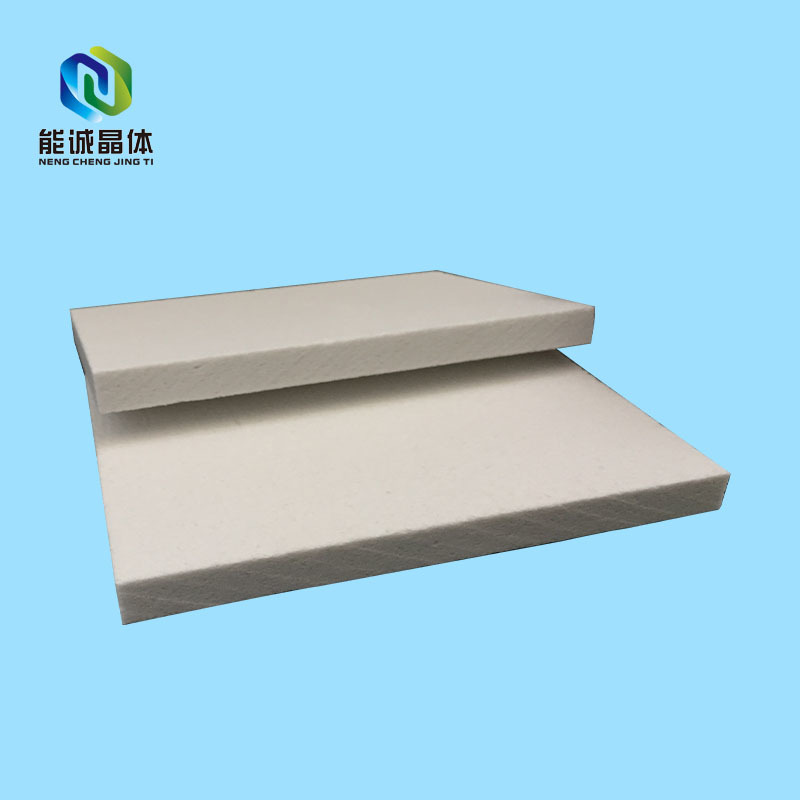

Aluminum silicate fiber refractory board, is a kind of aluminum silicate fiber as the main raw material, after a special process into the plate. Its core charm lies in its excellent fire resistance, which can maintain structural stability at extremely high temperatures, without softening or melting, and effectively isolate the erosion of high temperature on equipment or building structures. This feature makes it an indispensable "fire shield" in environments that require high-temperature operations or protection ".

2. application: guard safety and improve efficiency

1. The guardian of industrial furnaces: In the furnace lining of steel smelting, glass manufacturing and other industries, aluminum silicate fiber refractory board has the characteristics of light weight, high strength and low thermal conductivity, which not only reduces the weight of the furnace body, but also improves thermal efficiency and reduces energy waste. It is a secret weapon for professionals to improve production efficiency.

2. Pipeline and equipment insulation: high temperature pipeline and equipment insulation protection is the key to safe production. The aluminum silicate fiber refractory board can effectively reduce the surface temperature, prevent heat loss and burns, and create a safer working environment for the workplace.

3. New choice for building fire protection: With the improvement of building safety standards, aluminum silicate fiber refractory panels are widely used in firewalls, fire doors and other parts of high-rise buildings because of their good fire resistance and heat insulation performance. The life and property safety of the public has built a solid line of defense.

3. future trends and challenges:

With the continuous progress of science and technology and the continuous expansion of the industrial field, the application prospect of aluminum silicate fiber refractory board is becoming more and more broad. However, in the face of increasingly stringent environmental regulations and intensified market competition, how to further improve its environmental performance, reduce production costs, and achieve sustainable development has become a challenge that professionals and the entire industry need to face together.

At the same time, we should also think about how to better integrate this high-quality material into the intelligent and automated production process to improve production efficiency and reduce the risk of human operation. This is not only a challenge to technology, but also a test of the innovative thinking and cross-border cooperation ability of professionals.

Aluminum silicate fiber refractory board, as a bright pearl in the field of industrial protection, with its unique fire resistance and a wide range of application scenarios, has become an important tool for professionals to ensure production safety and improve efficiency. In the future, it will continue to play an important role in leading us to explore a safer, more efficient and environmentally friendly industrial future. The realization of all this is inseparable from the joint efforts and wisdom of every professional.

Related News

What are the main problems with aluminum silicate fiberboard?

Aluminum silicate fiberboard material is currently a high-performance insulation material. Aluminum silicate fiberboard has excellent properties such as light weight, low thermal conductivity, good heat resistance, aging resistance, easy bonding with other substrates, and no molten droplets during combustion. In Europe and the United States, it is widely used as an insulation material for building roofs, walls, ceilings, floors, doors and windows.

What are the characteristics of aluminum silicate fiberboard?

Aluminum silicate refractory fiber products are made by selective processing of pyroxene, high-temperature melting, blow molding into fibers, solidification molding, and different processes to produce blankets, blankets, boards, pipe sleeves, and other products. Aluminum silicate fiberboard has the characteristics of light weight, non combustible, moisture-proof and hydrophobic, low thermal conductivity

What is the structure of high alumina ceramic fiber board

1、 Shaped ceramic fiber furnace lining for high alumina ceramic fiber board The shaped ceramic fiber furnace lining of high alumina ceramic fiber board mainly refers to the furnace lining composed of formed refractory materials such as fiber blankets, fiber felt, fiber boards or fiber components. Structurally, it can be divided into two categories: layered structure and composite structure.

Analysis of alumina fiber properties and application prospects

Alumina fiber (polycrystalline mullite fiber), compared with carbon fiber, silicon carbide fiber and other non-oxide fibers, alumina fiber not only has high strength, high modulus, high temperature resistance and other excellent properties, but also has very good properties. High temperature oxidation resistance, corrosion resistance and electrical insulation. Alumina fiber (polycrystalline mullite fiber) can be compounded with resin, metal or ceramic to prepare high-performance composite materials, which are widely used in aviation, aerospace, military and high-tech fields.

What is the purpose of alumina fiber

Regarding, many people may already know what it is and what it can do. But what? Do you know what it is used for? Today, let me take you to learn about the new material of alumina fiber!

As one of the seven strategic emerging industries in my country and one of the ten key development areas of "Made in China 2025", the new materials industry is a key field in the "13th Five-Year Plan for National Science and Technology Innovation", which is the industrial basis for the transformation and upgrading of the entire manufacturing industry. .